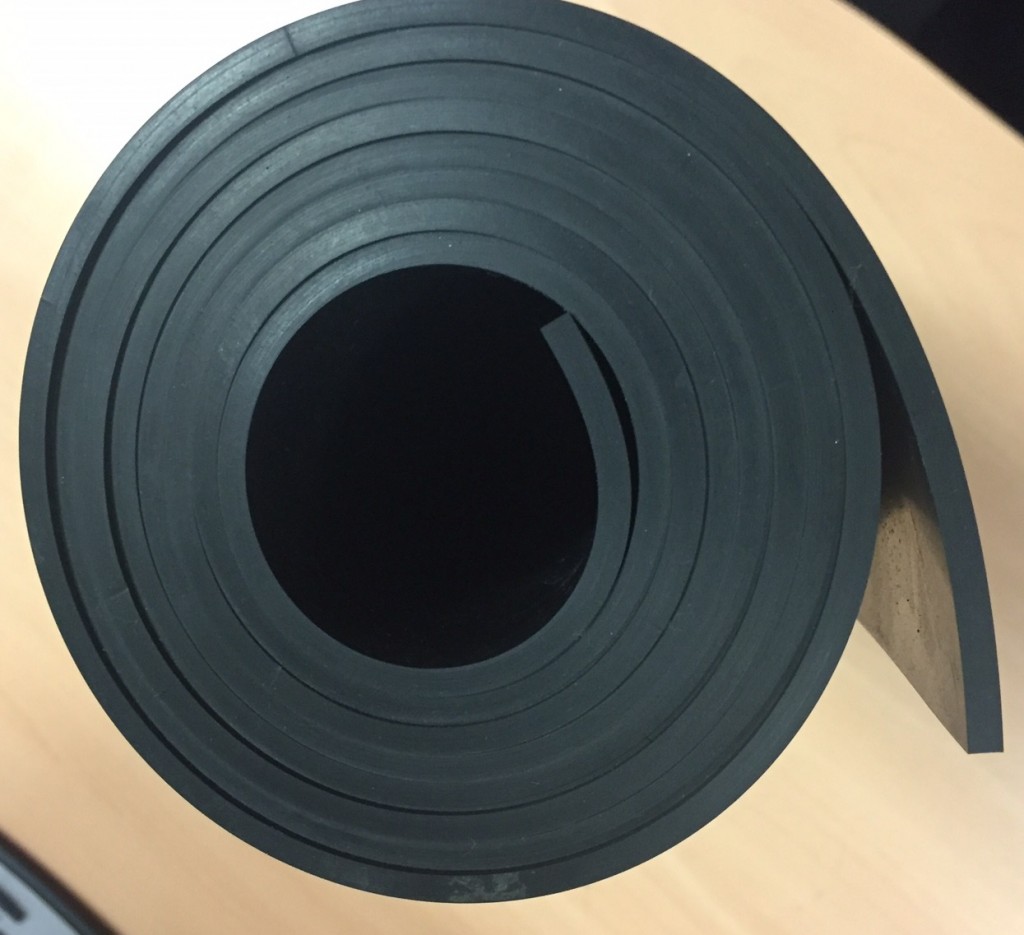

EPDM rubber (Ethylene Propylene Diene Monomer [M-class]) is an elastomer characterised by a wide range of applications. The ‘M’ refers to its classification in ASTM standard D-1418 and the ‘M-class’ includes rubbers having a saturated chain of the polymethylene type.

Applications suitable for EPDM

EPDM rubber is used in seals, o-rings, glass-run channels, radiators, garden and appliance hose, tubing, pond liners, washers, belts, electrical insulation, solar panel heat collectors, and speaker cone surrounds. It is also used as a medium for water resistance in electrical cable-jointing, roofing membranes, geomembranes, rubber mechanical goods, plastic impact modification, thermoplastic, vulcanizates, and many other applications

Advantages to using EPDM

EPDM sheeting has excellent water resistance, both fresh and salt, as well as being very good with ozone, UV and oxidation. The temperature and weathering properties of EPDM rubber sheeting are also outstanding.

These factors make EPDM ideal for use in water and it is often the material of choice for potable water applications. There are WRAS approved materials available for use in specific applications but, in more general terms, EPDM is a good all-round commercial material. It is widely used as a lower cost polymer, with good processing abilities.

Disadvantages to using EPDM

EPDM exhibits unsatisfactory compatibility with most oils, gasoline, kerosene, aromatic and aliphatic hydrocarbons, halogenated solvents, and concentrated acids. The very inert nature of the material also means it is difficult to adhere to, and this can be a limitation.

We made EPDM rubber waterproof sheet . If you are interested in these parts, you can feel free to contact us.